Tools #

- Hot air rework station

- No clean liquid flux (knock off Amtech stuff from eBay)

- Tweezers

- Good quality desoldering wick with flux in (Chemtronics soder-wick)

- Kapton tape (heat resistant - for shielding nearby components - especially plastic parts from the heat of the heat gun)

- Temperature controlled soldering iron, with a fine conical tip

- Eye protection

Steps taken #

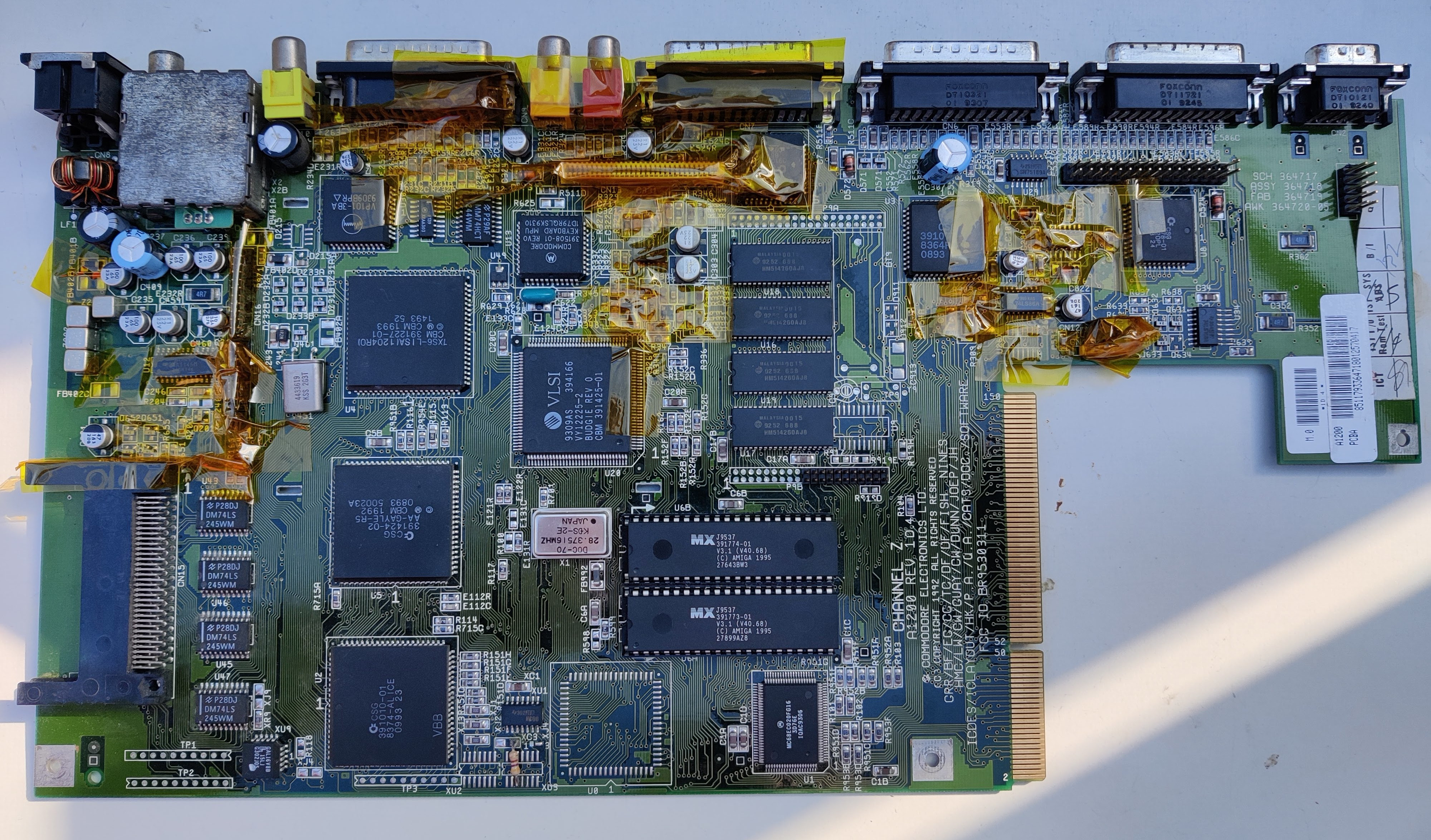

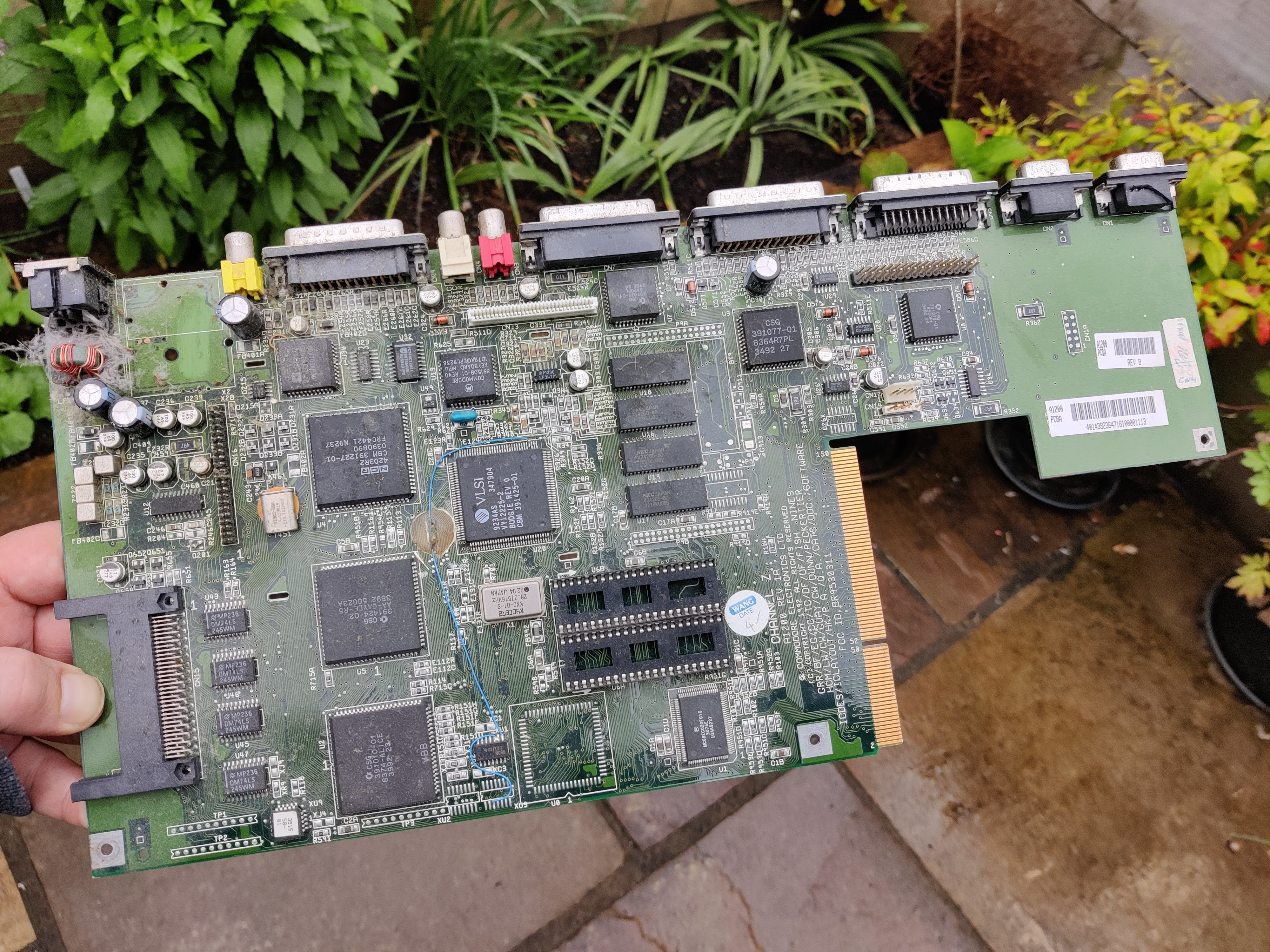

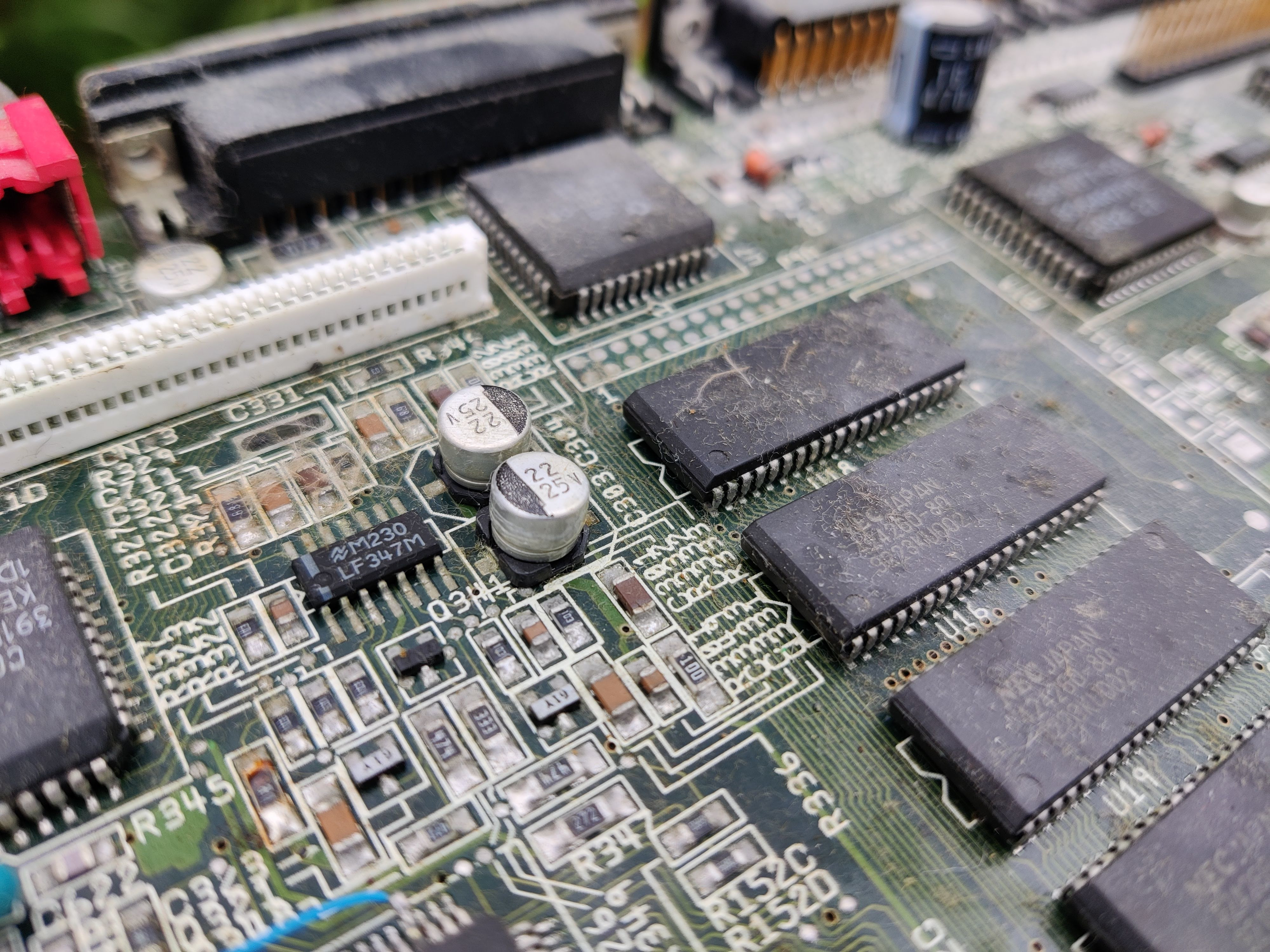

- Take a photograph of the board before doing anything

- Tape around the caps to be removed with kapton tape, taking special care to adequately cover the ports near to the caps that will be very close to the hot air

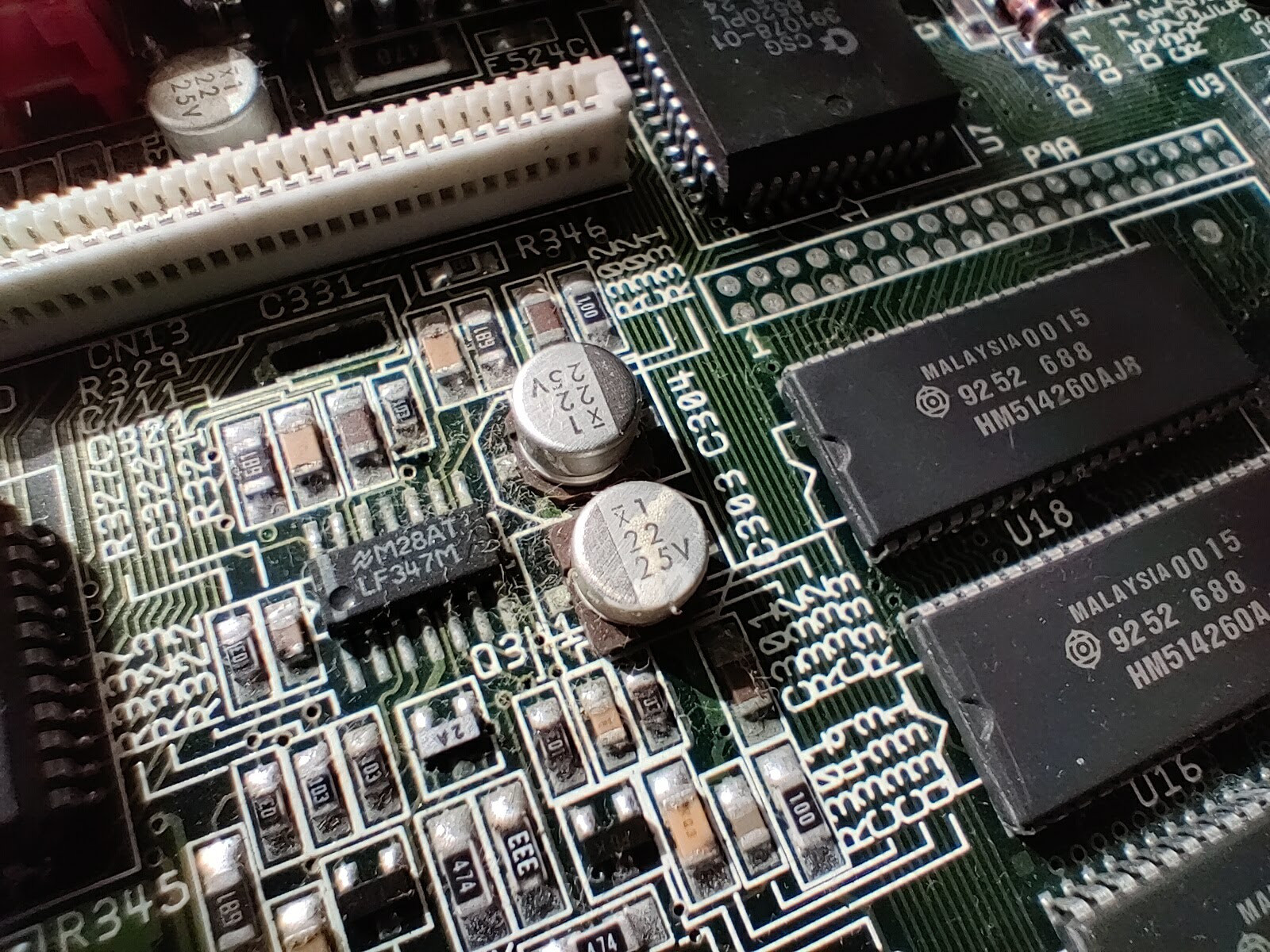

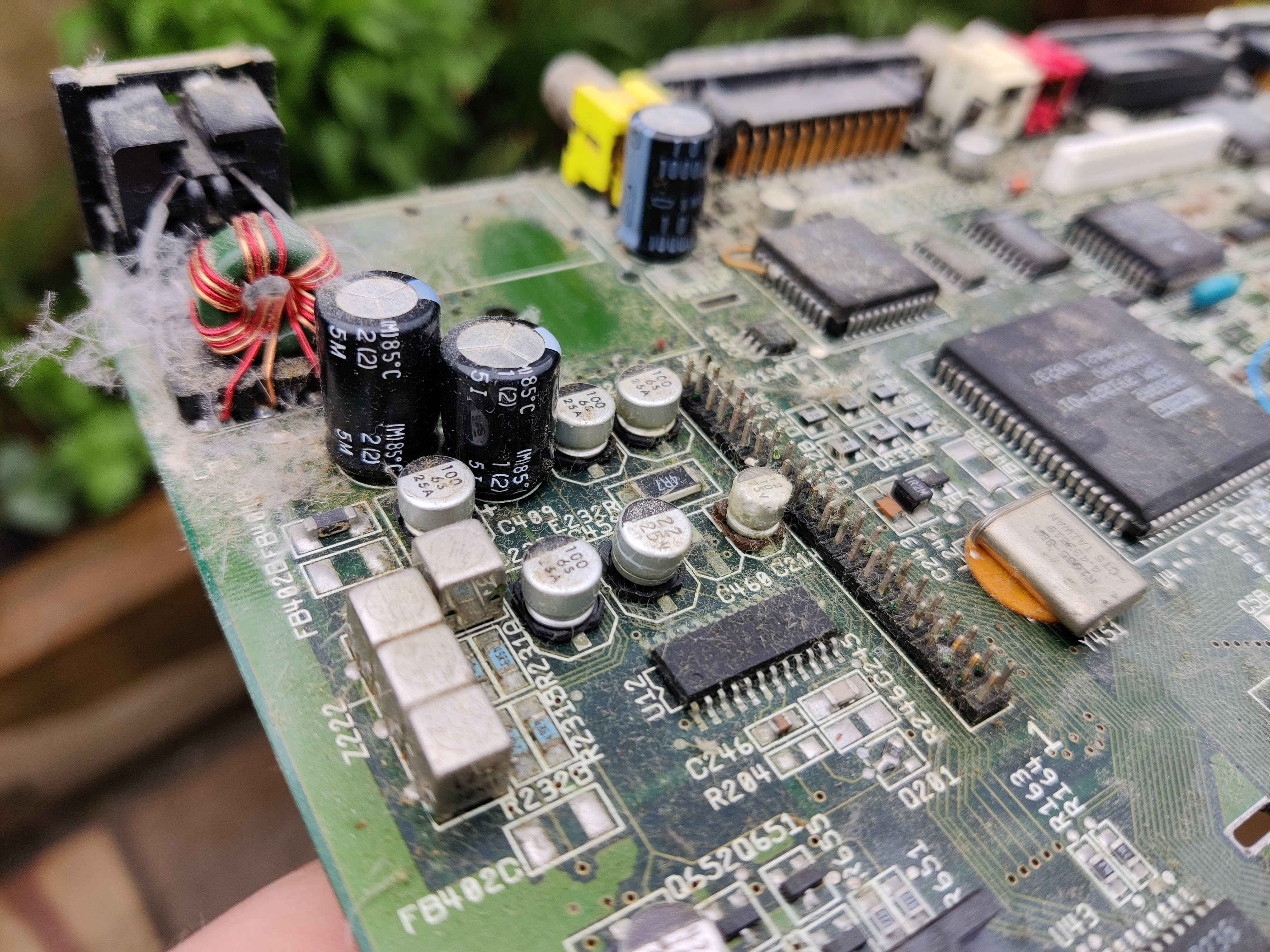

- Using the hot air station, remove the surface mount caps from the board. I found a temperature of 300degrees, 50% airflow was adequate for removing the caps, taking about 30seconds to 1 minute per capacitor. My strategy was to apply some of the liquid flux, then aim the hot air directly at the cap. Out of the 14 SMD caps on the board, 2 had already “popped” - the rubber bung in the base of the cap had popped out, and 2 popped while removing them from the board, one gently one more violently. Hence why it’s a good idea to wear glasses!

The name of the game is to remove the components from the moard with zero damage to it. To do this, we want to apply minimal physical stress to the board. Don’t try and pull the components off before they are ready to go. while using one hand to heat the area with hot air, keep gently tapping the component with the tweezers until it moves freely.

The SMD components proved easy to remove. The through hole capacitors however proved rather more troublesome. 2 of the TH caps are directly connected to large ground planes, with no thermal reliefs. This means all the heat from your iron is drawn away and you end up having to heat a very large area! one of the caps, is connected to a ground plane connected to the modulator, so you are heating that as well! I think in the future I will probably not bother replacing the TH caps. They were a decent brand on my board (Shoei - I thought they just made Motorcycle helmets?! :D) and apparently don’t leak often.

If I were to attempt this again, my approach would be to use some sidecutters to cut the cap in half, introduce some flux and new solder to the joint, and then attempt to remove each half individually.